Large-scale wind turbines produce vast amounts of clean power. For example, in the United States the average wind turbine produces about 843,000 kWh per month. That’s enough to power over 900 U.S. households. But, as with any very tall structure, wind turbines are susceptible to lightning strikes. While the odds of a person being struck by lightning are less than one in a million, the odds of a turbine being struck by lightning are a lot higher.

One study of offshore turbines found that 5.56 out of every 100 blades were damaged by lightning per year. Lightning is the main cause of wind turbine fires. According to the Finnish instrument manufacturer Vaisala, lightning damage accounts for 60 percent of blade losses and costs more than $100 million each year.

About Lightning Protection Systems

Large-scale wind turbines can be taller than 100 meters. When lightning strikes a turbine, it can cause severe damage to critical components such as wind turbine blades, which leads to costly repairs and downtime. To address this reality, wind turbine manufacturers integrate comprehensive lightning protection systems into their blade and turbine designs. Blade lightning protection systems contain several components, including lightning receptors on the blades and a downconductor cable that runs through the blade to the grounding system. The system works by channeling lightning energy away from sensitive components, such as the turbine blades and generators, so the turbine can stay online. Lightning protection systems are essential for producing wind energy at scale — which is why our customers need to know if the systems are working properly.

Zeitview’s Lightning Protection System Testing Solution

At Zeitview, we inspect a lot of wind turbines all over the world. So it’s not surprising that, over the past few years, our customers have been asking us to help them test lightning protection systems while we’re onsite inspecting their turbines.

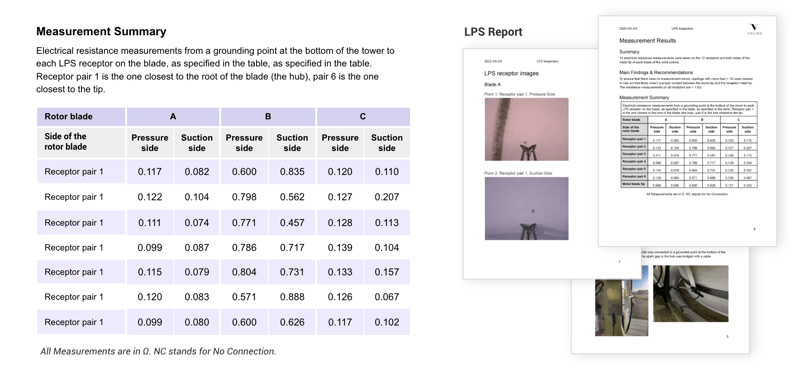

We wanted to provide a solution for our customers that could test lightning protection systems with a high degree of reliability. As I investigated solutions and components, I learned some important things, for example, checking continuity is not enough because damaged conductors can still pass the test. To test accurately, low resistance conductivity testing must be performed. We also wanted to conduct our inspections faster than with traditional methods, while maintaining accuracy, and without putting our technicians in harm’s way.

Utilizing Voliro’s proprietary drone we are able to conduct, safe, fast, and accurate testing of our customers’ lightning protection systems:

- Our solution uses a four-wire measurement for increased measurement accuracy (no need for resistance correction when using a two-wire measurement system).

- A fixed 0.20 amp current is applied to the circuit with a max voltage of 24 V. The measurement range is 0 to 1000 Ohms.

- Full-circuit resistance measurement from each receptor/metal tip on the blade to a grounded point at the bottom of the tower or blade root, if needed.

- Using the Voliro T’s ability to touch surfaces, thin metal needles push against the receptors with ~5lbs/2kg of force to ensure a robust measurement.

We are committed to proactive maintenance and keeping wind turbines in good working order to lower the cost of wind energy.

Here’s an example of the report our customers receive after a lightning protection system test:

How Should Lightning Protection System Testing Be Prioritized?

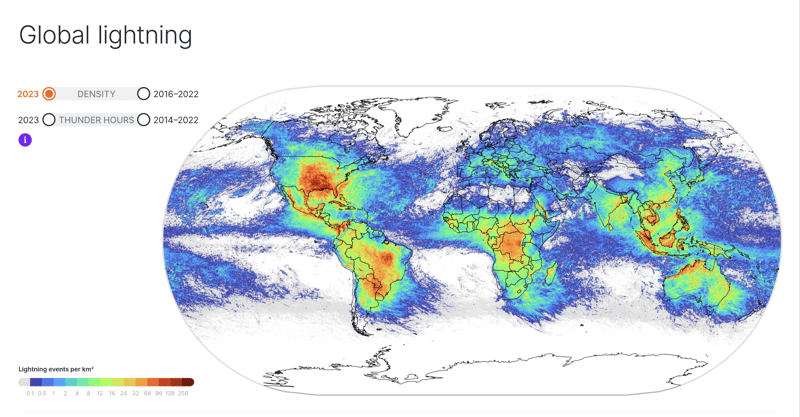

Any very tall structure is susceptible to lightning — which is inherently unpredictable. However, some areas of the world see a lot more lightning than others. This map, by Visalia, shows average lightning density by country. Clearly lightning risk can vary a lot by country. Even within a country, lightning strike frequency and density can vary drastically. For example, in the United States, the Gulf Coast experiences a very high rate of lightning strikes, while the West Coast experiences much less. The lightning density graphic you see here is contained in Vaisala's 2023 Lightning Density Report.

Because many of our wind energy customers operate sites all over the world, it makes sense to prioritize lightning protection system testing in those areas that have the most lightning.